All high-quality bongs use a variety of parts that have been designed to help ensure that the cleanest smoke possible could be produced. The humble downstem is one such component that is necessary for ensuring that the smoke can be transferred into the bong.

Here within this straight forward article, we will be going over everything there is to know about downstems.

Contents

What is a Downstem?

Simply put, a downstem is the section of tube that is used to draw the smoke through the base of the cone, into the bong’s chamber.

The rest of this section of the bong consists of two other parts. A suitable attachment that’s otherwise known as an outer stem, or adaptor, and the cone that is used to hold the cannabis material.

It is vital that the correct outer stem is used. It needs to be compatible with both the downstem and the cone. There are also many different types of cones available for use, and each style requires that a specific outer stem is used in order to be compatible with the downstem.

Consideration for Selecting a Bong Downstem

Before choosing the type of cone and outer stem that you want to use, it is important to use a downstem that’s compatible with the bong first.

There are three key things that you will need to consider to help ensure that the downstem is compatible with the bong itself. These are:

- The joint size (the opening)

- The length (of the stem)

- The material (of both the bong and the downstem)

1) The Joint Size

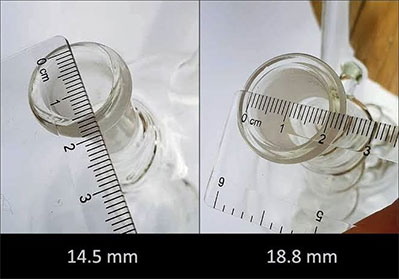

To determine the correct joint size, you will need to check the circumference of the opening where the downstem needs to be inserted into the bong.

For an effective airtight seal, it is vital that you pick a downstem that is as close to the size of the opening as possible. If the downstem is a loose fit, trying to create enough suction to pull the smoke down into the chamber can be near impossible.

If the downstem is too large it may not fit at all. Or worse yet, it could cause the bong to break if the fit is too tight and pressure is applied in the wrong direction as the downstem is inserted.

Most manufacturers will provide the correct information for the joint size that is needed. Some may require specific brands to be used, due to their design choice. Other brands may be designed to use any downstem of the correct size.

Just be sure to confirm if the opening has been made for a downstem, is measured in either inches or millimeters. Most downstem manufactures use millimeters, but handcrafted bongs in the US may use inches instead.

2) The Length

The downstem needs to be long enough to be submerged in the water that is inside the bong. If the downstem is too short, the smoke can not be filtered by the water, which could lead to you inhaling bits of burnt, or loose-leaf.

Just like with the joint size, most manufacturers will provide relevant information for the ideal length that is needed. If you are unable to find this information, there are two other methods you can try:

- You can try to find a downstem that is about half the length of your bong. This is not exactly an accurate method to use, but it does work for most bong designs.

- The other method is to try measuring the distance from the opening of where the downstem will be inserted, to the bottom of the bong. This can be done by using a ruler on the outside of the bong. Or for a more accurate measurement, simply place a pencil or rod through the opening, and mark off where the rest of it sticks out.

The downstem needs to be long enough to protrude outside of the bong, with enough additional length for the outer stem to be attached.

3) The Material

One of the more popular materials that are used to make bongs and their components these days, is glass. It is light, durable, and is tempered enough to not be affected by the heat from using the bong.

But this isn’t to say that downstems can only be found in glass. There are also ceramic downstems, wooden, stainless steel, and plastic models as well. While it may be that you prefer the flavor that some of these materials can help to produce, it nevertheless remains important for you to choose a material that is compatible with the material that your bong is made of.

If you choose a heavier material and the bong has been designed to be used with a lighter glass downstem, it could cause the bong to crack under the weight. Additionally, some materials can shrink or expand with temperature changes, which could also have an effect on the airtight seal that is needed.

Then there are the disposable downstem options. Some of these are made with the cone and outer stem as part of the downstem, with the intention of having this section discarded after use. In some parts of the world, a length of rubber garden hose is often cut to length as a cheap downstem alternative.

What is a Diffuser or Percolator Downstem?

There are two different downstem designs. There’s the straight tube design that releases the smoke into the water through a large opening at the base of the downstem. Then there’s the filtration design that releases the smoke through a series of small holes or slits, as opposed to the one larger opening.

The later design is known as a diffuser or percolator downstem. The idea is to have as much of the smoke make contact with the water as possible. When smoke is drawn down into the water, it is released as an air bubble, with only the smoke on the outer edge of the bubble making contact with the water.

By creating multiple smaller bubbles, more of the smoke can pass through the water. This helps to remove more of the bitter-tasting residue, ash, and loose-leaf that can be sucked through as well, producing a smoother, crisper tasting smoke.

Homemade Downstems – How to Make Your Own Bong Downstem

For our more crafty or budget tight readers out there, there are several different methods that you could use to make your own downstem.

Easy to Make Downstems

In truth, any cylindrical object, be it a rubber tube, garden hose, or even a pen, could be used as a downstem. It just needs to be able to fit into the joint hole of the bong.

The biggest downside to using these materials is that they tend to be susceptible to the heat and smoke from lighting the cone, and will need to be discarded after use.

Handcrafted Downstems

If you like to be a little more hands-on, here are two of our favorite ways to make a downstem. If made well, a handcrafted downstem could last you a while. Just be sure that it is easy to clean, that there are no sharp edges left behind, and that the materials are clean and free of hazardous oils or chemicals.

1) Wired Downstem

Try wrapping some stainless steel or copper metal wire around a rounded object to get the shape and size that you desire. The wire that sits on the outside of the bong will need the spaces in between each of the coils sealed off. This will make it easier to pull the smoke down into the bong’s chamber. But the wire inside of the bong could be used to take full advantage of the openings, by using them as a built-in diffuser, releasing the smoke into the water through the tiny slits.

Here is an example of a machine-made spring doorstop. With some ingenuity and skill, you could make a similarly shaped downsteam of your own.

2) Aluminum Downstem

How about rolling your own downstem out of a soda can. Remove the top and bottom of the can, and lay the leftover material on a flat surface. Now simply start by rolling the aluminum skin into either a cylinder or a cone shape, being careful not to cut yourself on any sharp edges. Glue the last fold in place and leave it to dry under some weight. Now you can use it as is or drill some small holes into the base of your new downstem to create some diffuser holes.

Here is an example made out of aluminum foil:

How Can I Make it a Tighter Fit?

Regardless of if you are using a preexisting objects as your downstem, or if you have handcrafted your own, if the joint size is too small for the opening in the bong, you need not fret too much.

Simply take an elastic band or some electrical tape, and wrap them around the section of the downstem that the bong will be holding onto. This will thicken the girth of the stem, allowing for a more snug fit.

To help give the downstem a more airtight seal, either use electrical tape, or something similar to silly putty. All you need to do is to block off the join around the downstem. Wrap the tape around the downstem so that it makes contact with both the bong and the stem itself. If using some form of putty, cram it into the gap, and build it up around the edge where the bong and stem meet.

You could also use a silicone sealant if you wanted. But if you need to remove the downstem at some point, you will need to cut it out and wait for it to dry again if you were to put it back in at a later date.

Final Thoughts

Choosing the right downstem isn’t all about personal taste and preference, it also has a lot to do with the type of bong you are using, and the style of cone you want to use.

Take your time when picking your bong. If you want to use a specific type of downstem, say one that you find provides additional flavor, then find a bong that can be used with that type of downstem.

Otherwise, prioritize your bong over your downstem, and find one that is either purpose-made for that bong design, or use one that is compatible with the bong itself.

Leave a Reply

You must be logged in to post a comment.